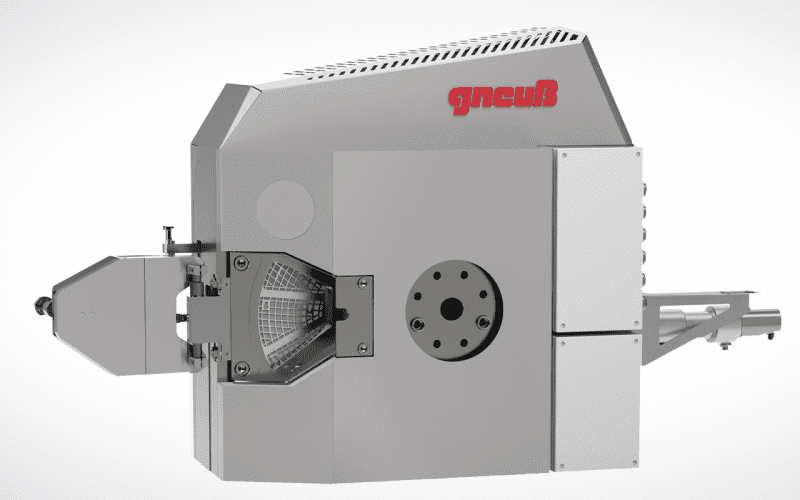

Gneuss filter technology for the production of nonwovens

Typical areas of application e.g:

hygiene products, substrates, textiles

- Focus materials: PE, PP, PET, PA 6, PA 66, PBT

- Typical throughput up to 2,000 kg/h

- Typical filtration fineness up to 6 µm

The necessary spinning quality across all spinnerets in the production of spunbond fabrics requires the careful removal of existing inhomogeneities before entering the spin beam. Additionally, high process consistency in pressure and temperature is an essential prerequisite for efficient production. The high throughput rates necessitate a fully automatic filtration system that operates without impacting the process. The RSFgenius and the SFXmagnus have been specifically developed to meet these requirements, enabling you to continuously reduce costs in the manufacturing process while achieving top quality.

Key features of rotary filtration

- Material consistency due to very short melt residence time

Thermal degradation of the melt is prevented and viscosity remains constant. In this respect, the RSFgenius differs significantly from conventional candle or disk filters. - Longer spin pack life

The process-consistent operation of the RSFgenius and SFXmagnus does not affect the spinning process. This remains true throughout the year. Prefiltration of 20µm or finer directly before the spin pack is possible, so that the spin pack can be used primarily for melt homogenization. - Reduction of filament breaks (slubs)

Higher melt purity improves spin pack specification, resulting in more homogeneous melt quality and consistent melt flow. As a result, slubs, which are a visual nuisance in low basis weight spunbond fabrics, can be eliminated. - Material cost reduction

The use of the RSFgenius with integrated screen cleaning allows a higher proportion of recycled material (up to 100%) without compromising product quality. This results in a reduction in material costs. - Maximum system availability

Filter changes without interrupting production and the fully automatic operation of the RSFgenius ensure maximum system availability.